Offering a range of storage options – from sensible heat to latent heat and thermochemical storage – Thermal Energy Storage (TES) is a sustainable contributor in renewable energy management.

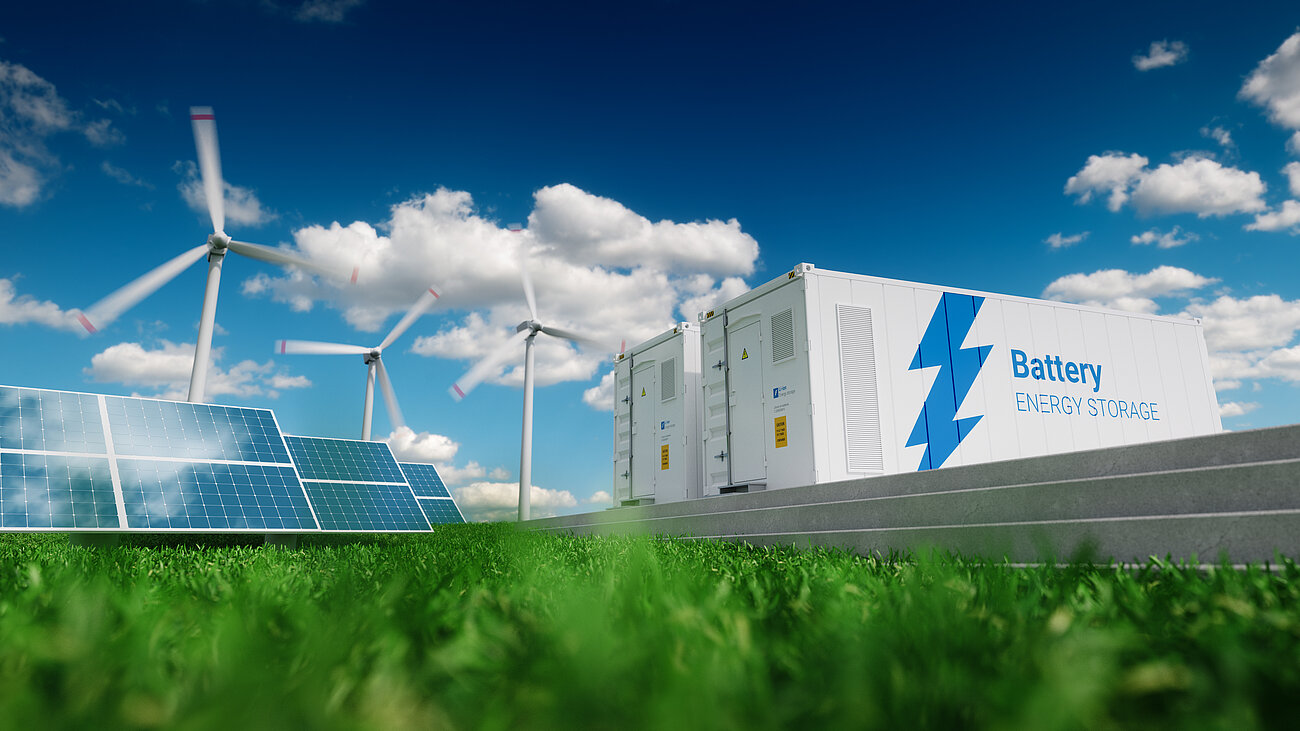

However, most renewable energy sources are intermittent by nature. This is where energy storage steps in as a game-changer.

While the most common form of energy storage is battery technology (BES), innovations are continually emerging in the field. For instance, thermal energy storage systems (TES) can capture heat during the daytime and release it at night for heating purposes. Likewise, chemical storage solutions are being explored to hold onto energy for more extended periods without degradation.

Offering a range of storage options – from sensible heat to latent heat and thermochemical storage – Thermal Energy Storage (TES) is a sustainable contributor in renewable energy management.

Battery Energy Storage (BES) is not only a rapidly expanding segment but is also the epicenter of technological innovations and optimizations.

The Lohtragon® metal salts contribute to a sustainable energy generation and storage across various types of energy. In many systems these high performance metal salts act as active component like in thermal energy storage and batteries. In other energy sectors metal salts are used as auxiliary materials and to optimize production processes, e.g. as hydrogen sulfide scavenger in biogas plants.

With our Joint Lohtragon® Product Development approach your specific needs and requirements to energy storage systems are our objective.

Energy storage is not merely an adjunct to renewable energy but a critical enabler. As technologies continue to evolve, the potential for efficient, sustainable energy storage systems grows ever more promising – supported by Lohtragon® metal salts.

Sample Request

Product Finder

Contact